A concrete compressive strength testing tool is one of the key tools to ensure the quality of concrete in various construction projects, ranging from highways, bridges, to high-rise buildings. Concrete itself is a mixture of cement, sand, gravel, and water that must be of good quality to ensure a strong and durable structure.

There are reinforced and non-reinforced concretes, where reinforced concrete is equipped with steel reinforcement to increase elasticity. To ensure that the concrete used meets the standards, testing with a concrete compressive strength tool is essential.

To help you choose the one that best suits your project needs, read the discussion about the types of concrete compressive strength testing tools and how to apply them in this article.

What Is a Concrete Compressive Strength Test?

A concrete compressive strength test measures how well concrete withstands a load before cracking or failing. This test is important for assessing the quality and compressive strength of concrete while also ensuring the safety of a building.

Typically, concrete is tested in the form of cubes or cylinders using a press machine, and the results are expressed in units of MPa or psi. Concrete that has undergone curing is usually tested at certain ages, such as 7, 14, or 28 days, to evaluate the development of its strength.

This value is called concrete compressive strength and is usually measured in units of MPa (megapascals). The test specimens generally take the form of cubes or cylinders, allowing gradual monitoring of changes in concrete strength over time.

Types of Concrete Compression Testing Machines

Types of concrete compression testing machines are divided into three main groups, namely:

- Manual machines: Use a hand-operated hydraulic pump, suitable for small laboratories.

- Semi-automatic machines: A combination of manual hydraulics with digital reading.

- Digital UTM machines: Automatic systems with advanced sensors, providing accurate results, and integrated data.

Read also: Types of Concrete Test Techniques for Construction Projects

Concrete Compressive Strength Testing Tools

Various tools are used to test the strength of concrete to ensure that constructions remain safe and meet standards. Each tool has its own working method and function, so it is important to choose the right one according to the project's needs. Here are some types of concrete compressive strength testing tools:

1. Digital Resistivity and Carbonation Test

The Digital Resistivity and Carbonation Test measures the likelihood of corrosion in concrete reinforcement by assessing its electrical resistivity. More permeable concrete has lower electrical resistance, allowing the corrosion rate to be predicted.

The testing process is quite simple, namely by drilling two small holes, inserting conductive gel, attaching the probe, and the device will display the resistivity value directly.

2. Ground Penetrating Radar (GPR)

Ground Penetrating Radar uses electromagnetic waves to detect objects or damage inside concrete, such as voids, honeycombing, delamination, and other types of damage. This tool can also indicate the position of reinforcement, the thickness of concrete layers, as well as overlay boundaries, making it commonly used for building surveys.

3. Core Drill

A Core Drill is a cylindrical tool used to bore holes in concrete surfaces and to take core samples. The drill bit is usually coated with diamond or carbide, and the machine consists of a motor, handle, and drill bit.

Core drilling allows the extraction of cylindrical samples from concrete, known as core samples, which is different from regular concrete drilling or cutting. There are two types of core drills, namely electric and engine-powered, differing in their power source.

4. Rebar Detector

A rebar detector is used to detect steel reinforcement (rebar) within concrete to prevent drilling errors. This tool utilizes an electromagnetic field influenced by metal, working similarly to a metal detector by scanning the concrete surface.

5. Hammer Test

The Hammer Test is popular because the tool is portable and lightweight. The concrete hammer test is performed by striking the concrete surface with a certain mass, then measuring the rebound that occurs. The greater the rebound, the harder and stronger the concrete surface is.

Read also: Concrete Grade: Types and Classification Table

6. Ultrasonic Tomograph

An Ultrasonic Tomograph is similar to UPV in that it uses ultrasonic waves, but the results can be displayed in 3D. This tool allows you to detect reinforcement as well as cavities or voids within the concrete.

7. Ultrasonic Pulse Velocity Test (UPV)

The Ultrasonic Pulse Velocity Test (UPV) is a concrete testing tool that uses ultrasonic waves to measure the pulse travel time through concrete. The denser and more homogeneous the concrete, the higher the recorded pulse velocity. This method is a non-destructive test (NDT), so it does not damage the material during testing.

8. Compression Testing Machine

The Compression Testing Machine is used in laboratories to compress cylindrical or cubic concrete samples until they crack or break. From this test, the compressive strength is calculated, and the crack patterns are analyzed to assess the concrete's ability to withstand loads per unit area.

Samples must be prepared according to specifications, including dimensions, conditions, curing, and concrete age, usually 3, 7, and 28 days, in accordance with ASTM C39 or SNI 1974:2011 procedures. Although destructive in nature, this method is very accurate, but it requires more time and higher costs.

9. Universal Testing Machine

The Universal Testing Machine (UTM) is widely used in modern laboratories to test concrete quality because it is more advanced compared to conventional machines. Initially, the UTM was developed for testing various materials, such as metal, wood, and plastic, but it is also effective for compressive testing of concrete.

Its advantages include high precision with digital sensors, versatility for tensile, flexural, and compressive testing, automatic data storage, and faster processing. With the UTM, concrete testing not only determines strength but also helps analyze the behavior of concrete when cracking.

Why Is the Compressive Strength Test Important?

The compressive strength test is important to conduct before starting a project to ensure that the concrete mix truly meets the expected strength standards. This test helps the concrete withstand external factors, such as weather, heavy loads, or earthquakes.

Additionally, this test is useful for detecting weaknesses in the mix, reducing the risk of structural damage, and ensuring the building's safety and long-term durability. Consistent test results also allow project managers to monitor concrete performance and make more accurate decisions in the future.

Concrete Quality Standards

The concrete quality standards in Indonesia refer to SNI 1974:2011, while the international standards commonly used are ASTM C39 (USA) and BS 1881 (UK). Concrete quality classification is usually indicated by numbers:

- K-225: Commonly used for residential houses.

- K-300: Suitable for multi-story buildings.

- K-500: Used in large infrastructure projects, such as bridges.

That is the explanation regarding various concrete compressive strength testing tools that are important to ensure the long-term quality and durability of buildings. Concrete testing is not just about technical aspects, but also a step to maintain safety, efficiency, and construction quality.

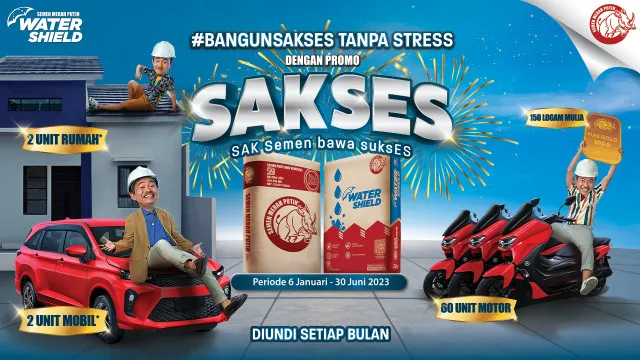

Besides conducting tests, make sure you use quality concrete materials, such as premium products from Semen Merah Putih. Through Beton Merah Putih, Ready Mix Concrete and Precast Concrete are available with high-quality standards designed for various construction applications with strong and reliable results.

If you are still unsure about choosing the right concrete type for your project, our team is ready to help. Contact us now to get complete information about Semen Merah Putih products that are suitable to support the success of your project!

Read also: Get to Know Manual Concrete Casting Measurements Based on SNI