One way to improve concrete quality is to use a concrete hardener. This additive can strengthen concrete's resistance to external factors, such as moisture and cracking.

However, to get the best results, you need to know the right concrete hardener ratio for the type of concrete you are using. This article will discuss how to calculate and adjust the concrete hardener ratio, as well as the steps to properly use it.

What Is Concrete Hardener?

Concrete hardener is an additive used to increase the strength, density, and durability of concrete surfaces after the casting process or on finished concrete.

This product works by seeping into concrete pores or reacting with cement compounds, making the concrete structure more compact, less dusty, and more resistant to friction and loads.

Concrete hardeners are commonly used on warehouse floors, parking areas, concrete roads, and industrial buildings to extend concrete's lifespan and maintain its surface quality. The application of concrete hardeners also helps reduce long-term maintenance costs as the concrete surface becomes more durable and stable.

Preparation Before Applying Concrete Hardener

Before applying concrete hardener, you need to prepare several things. These preparations will affect the final result of the concrete you are making. Here are some important steps you need to take:

1. Check the Type of Concrete Used

The type of concrete affects the mixture ratio and the amount of concrete hardener. Normal concrete and high-specification concrete require different amounts.

2. Prepare the Necessary Tools and Materials

Concrete hardeners are usually available in powder or liquid form. Make sure you have the right tools before applying the concrete hardener, such as digital scales for measuring powder or accurate liquid measuring containers.

3. Ensure the Concrete is in Optimal Condition

Before adding the concrete hardener, ensure that the concrete mixture is in good condition, with the appropriate moisture and viscosity. This will allow the hardener to penetrate more effectively.

4. Repair Cracks and Holes Before Application

Check for hairline cracks, small holes, and porous areas to ensure even hardening. Damaged spots can absorb excess material, leaving other areas deficient and uneven. Patch or repair the damaged areas, smooth them out, wait a few moments, and then continue with the application process.

5. Read the Instructions on the Concrete Hardener Packaging

Each concrete hardener brand has different instructions and steps for application. Read them carefully to ensure you follow the manufacturer's recommendations for the correct concrete type and ratio.

6. Conduct a Small Test

Before applying the concrete hardener to the entire surface, it is recommended that you conduct a small test first. Choose a limited area that represents the actual concrete conditions to ensure the suitability of the dosage, absorption, and final results after drying.

Read also: Self-Healing Concrete: Solution for Strong & Durable Buildings

How to Calculate the Ratio of Concrete Hardener

Calculating the ratio of concrete hardener is essential to achieve optimal results. Excessive or insufficient ratios can affect the strength and durability of the concrete. In this case, calculating the ratio of concrete hardener is quite simple, as follows:

- Calculate the area (m²) = length × width.

- Use the material requirement formula, which is area (m²) × product dosage/coverage (liters or kg per m²).

For example, if the floor area is 50 m² and the dosage on the packaging is 0.2 liters/m², then the basic requirement is 50 × 0.2 = 10 liters. After that, add a 5-10% reserve if the concrete is more porous/coarse or if the application uses a sprayer, so that the total is around 10.5-11 liters.

How to Apply Concrete Hardener

After determining the correct ratio, the next step is to apply the concrete hardener correctly. Proper application will maximise the effectiveness of the hardener and ensure that the quality of the concrete is maintained. Here are the steps you can follow:

1. Read the Dosage on the Product Label

You need to check the manufacturer's recommended ratio, expressed in ml/m², liters/m², or per kg of cement. Also note whether the product needs to be diluted or can be used directly, as this will change the total amount of material required.

2. Measure the Area of Concrete to be Applied

You must calculate the surface area (length × width) and separate the areas that will not be applied. If the area is irregularly shaped, break it down into smaller sections for a more accurate calculation. This area data is the main basis for determining the exact amount of hardener required.

3. Calculate Material Requirements

Multiply the area by the recommended dosage (e.g., 0.2 liters/m²), then add a 5–10% reserve to account for contingencies. If the concrete is more porous or the surface is rougher, the requirement may increase due to higher absorption.

Read also: Concrete Grade: Types and Classification Table

4. Prepare the Mixture According to the Instructions

If there are dilution instructions, follow the specified water-to-materials ratio. Use measuring tools such as measuring cups or marked jerry cans for accurate measurements and consistent quality. Next, stir until homogeneous to ensure an even application and consistent hardening.

5. Determine the Appropriate Application Method

You can use a sprayer for liquids to ensure quick and even application. Ensure the tool is clean and the nozzle is not clogged, as uneven application often occurs with malfunctioning tools. Select a method that allows you to easily maintain the thickness and evenness of the coating.

6. Apply Evenly and Avoid Overlap

Start from one side and move gradually so you do not step on any still-wet areas. Maintain a consistent spray/roll pattern to avoid areas that are too wet or too dry. Too much overlap can leave residue and cause uneven colour or texture on the surface.

7. Conduct a Small Test

You should test on a small area to assess absorption, drying time, and the surface's final appearance. From this test, you can adjust the dosage, application method, or number of layers before applying to the entire area.

8. Wait for the Recommended Curing Time

After application, allow time for the hardener to react and bond optimally with the surface. Avoid walking on the surface during drying, as this can damage the unstable coating. If a second coat is needed, ensure the time interval is in accordance with the product instructions for maximum results.

Using hardening chemicals properly can increase concrete's resistance to extreme external conditions. However, ensure you also use high-quality concrete materials, such as Ready-Mix Concrete and Precast Concrete, to achieve optimal construction results.

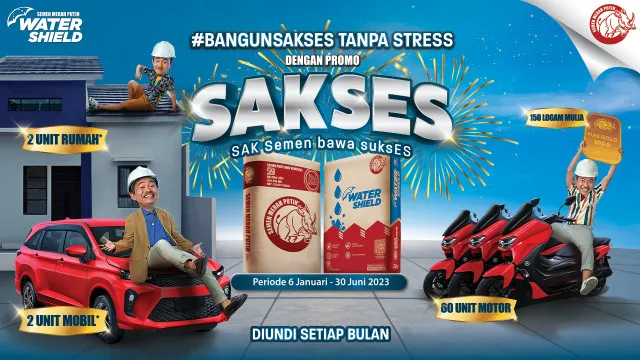

With high-quality concrete from Semen Merah Putih, you can build sturdy, durable structures. If you have any questions or would like to consult about your project, contact us now and get the best solutions to realise your dream building!

Read also: Concrete Bleeding: The Causes & How to Overcome Them